Field-tested solutions

with proven results

Discover a variety of solutions for energy, process, and production optimization, created in collaboration with our leading industry partners.

Performance Optimization in Process Compressors

Edit Content

Performance Optimization in Process Compressors

Challenge

- Unplanned downtimes lead to reactive and time-based maintenance which can be costly and inefficient

- Difficult to quantify metrics that correlate to valve health

Solution

- Use first principles to predict the efficiency and power in real-time

- Develop ML model to predict the anomalies in real-time leading to sub-optimal operations

- Email notifications for real-time deviations

- Recommendations to close the loop for optimal operations

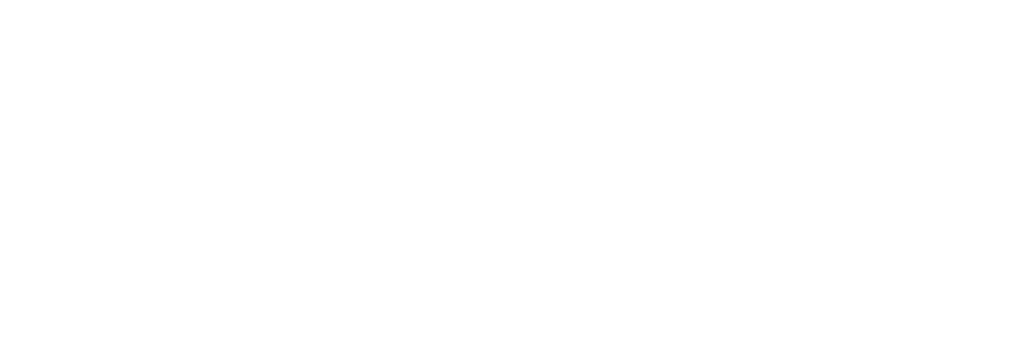

Result

- 2-5% reduction in energy consumption

- 45-50% Reduction in unplanned downtimes

Performance Optimization in Air Compressors

Edit Content

Performance Optimization in Air Compressors

Challenge

- More than required energy consumption due to sub-optimal operations

- Unnoticed deviations and losses in the compressed air network leading to excessive energy consumption

Solution

- Predicting the Performance and Health score of the compressors with early warnings

- Using process and mechanical parameters to predict the Ideal energy consumption against the actual consumption

- Email notifications for real-time deviations

- Recommendations to close the loop for optimal operations

Result

- 2-3 % reduction in energy consumption

- Reduction in GHG emissions by ~ 150 Tonnes of CO2/year

Performance Optimization for Heat Exchanges

Edit Content

Performance Optimization for Heat Exchanges

Challenge

- Fluid with dissolved impurities upon reaching saturation deposit on the inner tubes causing scaling

- Scaling was leading to corrosion and improper heat transfer

Solution

- Using ML to create a PdM model to allow personnel to take necessary action before reaching impurities saturation

- Parameter creation of Overall Heat transfer Coefficient(U) that varies with time

- Employing physics-based features to predict fouling

Result

- Reduction in unplanned downtimes by >50%

- Savings of around $1M

Multi-effective Evaporator – Steam Optimization

Edit Content

Multi-effective Evaporator – Steam Optimization

Challenge

- Includes frequent thermal breakdowns due to fouling

- More than required steam consumption leading to sub-optimal operations

Solution

- Create a soft sensor for overall heat transfer coefficient and set alarm limits

- Benchmark and compare the real-time steam consumption with respect to the ideal consumption

Result

- Steam optimization by ~ 15-20%

- Reduction in unplanned maintenance by 55-60%

- Reduction in cost of maintenance by 12-15%

Productivity Improvement Blast Furnace Operations

Edit Content

Productivity Improvement Blast Furnace Operations

Challenge

- Complex and dynamic conditions with various parameters makes it difficult to detect hanging incidents in real-time

- Difficult to monitor Silicon content of the molten iron which is an important indicator of the furnace temperature variations

Solution

- ML based models to predict the deviations in the furnace operations – correlated with hanging

- Predict silicon content in real time using the historical data

Result

- 2-3% Increase in blast furnace productivity

- ~ 450-600k Savings annually

Feed Strategy Optimization in Aluminum Smelters

Edit Content

Feed Strategy Optimization in Aluminum Smelters

Challenge

- Difficult to maintain the bath temperature and excess ALF3 in the specified range

- Shift engineer experience driving ALF3 addition directly impact the performance of the smelters productivity

Solution

- Advanced Conditioning for identifying the deviations in the bath temperature and excess ALF3

- Used historical data to model the required ALF3 feed to be added for optimal operations

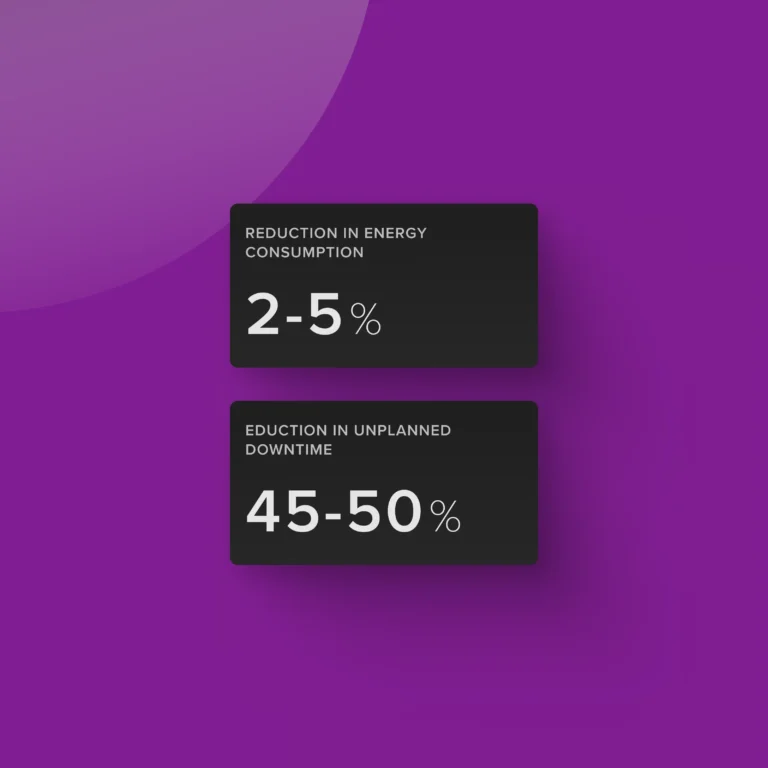

Result

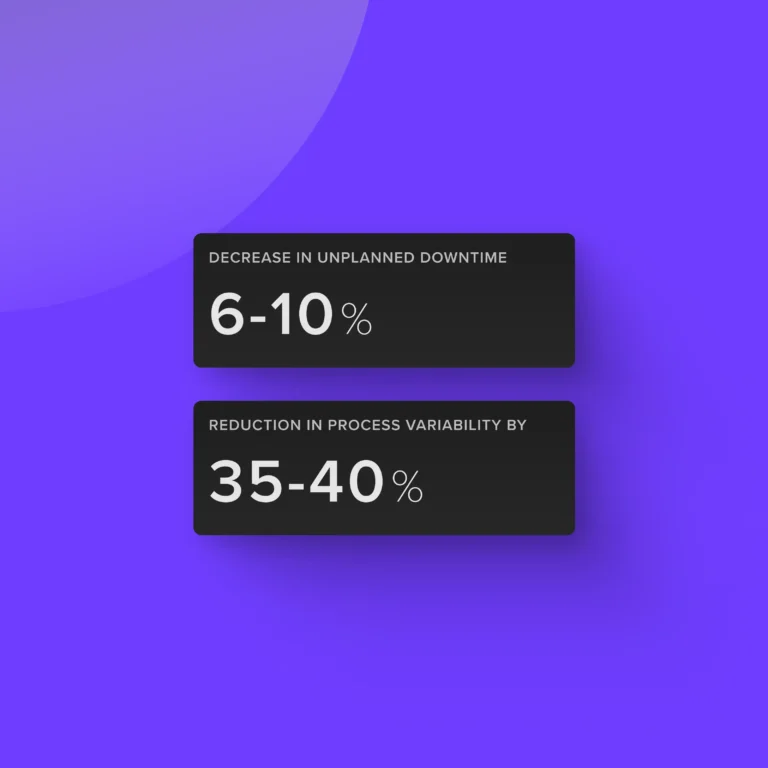

- 6-10% decrease in unplanned downtime

- Reduction in process variability by 35-40%

Furnace Efficiency Prediction

Edit Content

Furnace Efficiency Prediction

Challenge

- Ethylene furnaces coke (foul) during cracking operations resulting in a loss of efficiency

- Improper decoking resulting in equipment damage and lost production time

Solution

- Identify different phases of decoke operation and excessive hold times

- Predict decoke effectiveness with KPIs like temperature recovery and run time between decokes

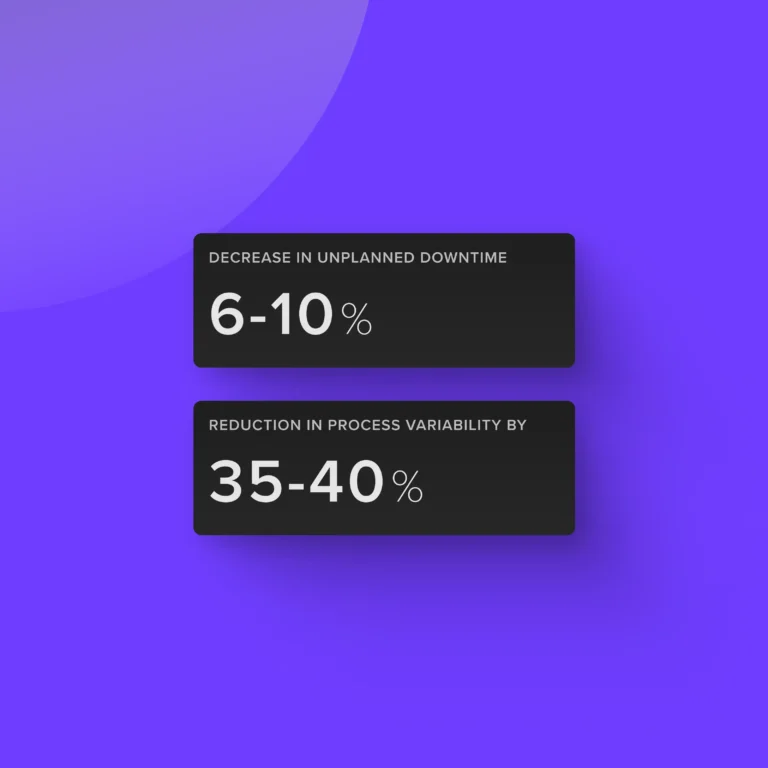

Result

- Tracking decoke effectiveness metrics identified procedural inefficiencies and inconsistency in execution

- Optimization of decoke procedures reducing hold time and dead time has resulted in an additional $250k/y in production.

Distillation Column Efficiency

Edit Content

Distillation Column Efficiency

Challenge

- Changes in feed quality impact the efficiency of columns

- Frequent vacuum pumps/ reboilers and condenser failure causes operational upsets

Solution

- ML-algorithm based PdM model for vacuum pump and reboiler

- Employing Data Analysis to understand trends and create indicators to drive predictions

- Employing first-principle based equations to understand status of machine

Result

- 23% decrease in downtime

- Increase in efficiency by 8-10%

- ~ 250k Savings annually

Boiler Efficiency Prediction

Edit Content

Boiler Efficiency Prediction

Challenge

- High variations in fuel quality and feed leads to operational challenges in maximizing the steam generation

- Degradation of boiler efficiency leading to suboptimal combustion strategies

Solution

- Maintaining enthalpy balance in boilers for incoming streams and generated steam to track the efficiency in real-time

- Predicting the efficiency degradation and recommending the corrections to counter impact the fuel quality variations

Result

- Optimal Steam to fuel ratio

- 4-7 % energy savings/ year

- Reduction in greenhouse gas emissions of 200 tonnes of CO2 per year

Cooling Tower Health Monitoring

Edit Content

Cooling Tower Health Monitoring

Challenge

- Impact of seasonality and load requirements are unknown

- More than required energy consumption in fan, water losses

Solution

- Predict the energy requirements using advanced modeling to regulate the fan RPM

- Monitor and track the losses – evaporative, drift and blowdown of the water stream

Result

- Timely and effective maintenance for cooling towers

- Increased efficiency by 12-16%

Need a custom solution?

Please reach out if you need more details on a custom solution tailored to your specific needs. We collaborate with leading industry partners who have extensive experience developing with Kelvin for real-world applications.