Superpowers for your people

with Kelvin & Databricks

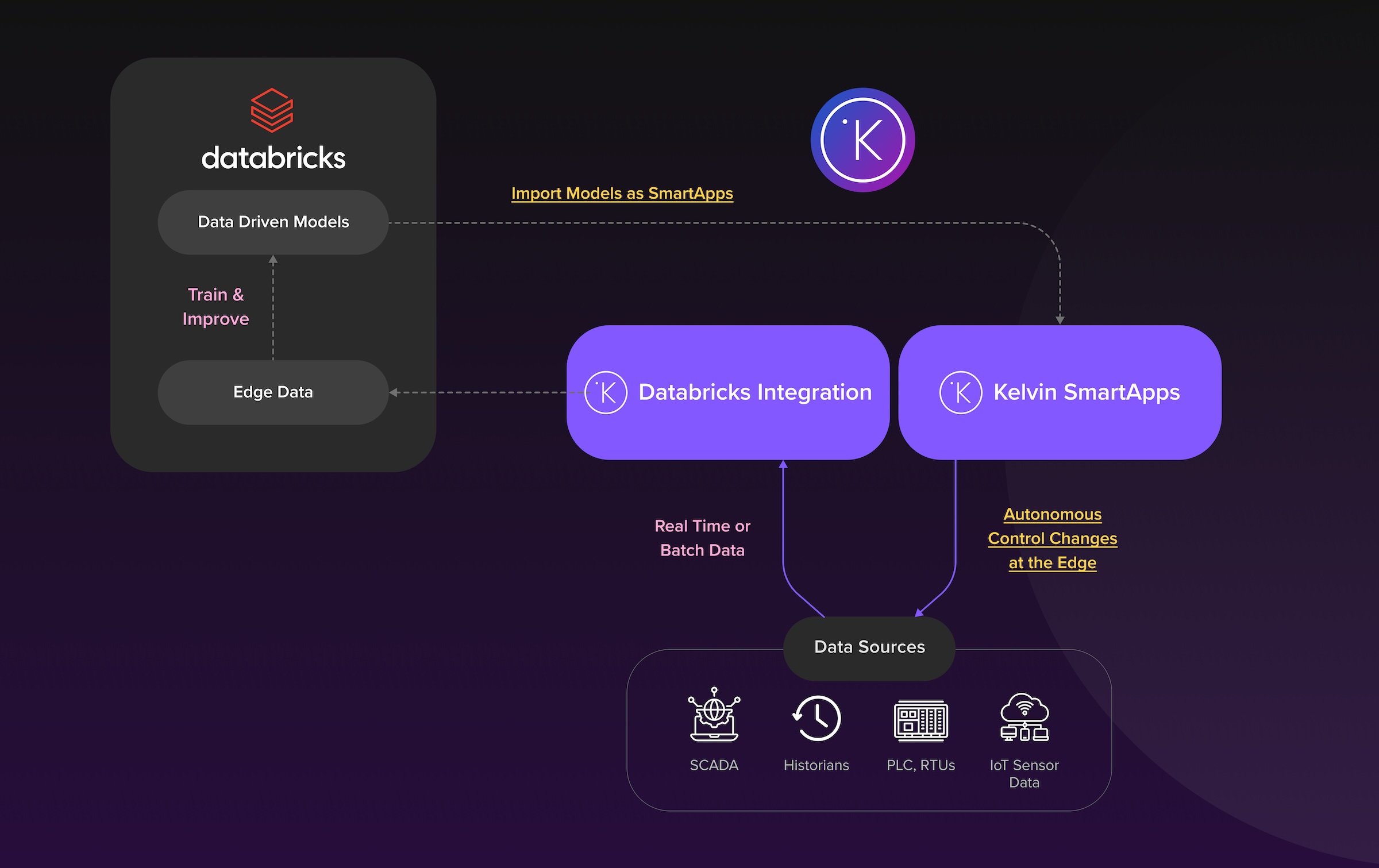

Databricks brings the Lakehouse for all your industrial data and the tools for Data Engineering and Intelligence. Kelvin delivers the System of Action to move from Insight to Impact.

-

Autonomous Operations

Kelvin’s platform enables customers to rapidly create and deploy AI-powered SmartApps and Agents that automate engineering decisions and optimize complex operations in real time. -

Unified Data & AI

Databricks brings together data, analytics, and AI across cloud and edge environments, providing the foundation for scalable, intelligent operations. -

From AI Models to SmartApps

Kelvin transforms AI models into SmartApps that deliver insights, automate control decisions, and monitor operations in the physical world safely and effectively. -

Proven Impact

Together, Kelvin and Databricks help manufacturers and energy operators increase throughput, reduce downtime, and standardize best practices - driving higher profits and strong ROI.

Overview

How it works

Turn your expertise into autonomous control — whether starting from scratch or using what you already know.

Ingest & Filter

Land OT/IT data streams and batches, standardize tags & metadata, determine the quality of the data.

Build & Validate Models

Train, evaluate, and register models; capture process constraints and KPIs.

Orchestrate & Act

Deploy and manage SmartApps to monitor assets, generate recommendations, and safely execute control changes through existing OT systems.

Learn & Govern

Feedback on models via annotation, performance tracking from changes, audit trails, and continuous improvement across sites and fleets.

Mission

Why Kelvin.ai & Databricks?

Unlock the potential of your business with faster insights, rapid deployment, and seamless interoperability.

Joint Industry Solutions

Energy & Manufacturing, Transformed

Unlock the potential of your business with more uptime, higher throughput, lower costs, and reduced emissions.

- Asset Performance & Reliability: Predict impending

failures on compressors, pumps, turbines; trigger optimized setpoints,

soft‑interlocks, generate work orders before problems escalate.

- Asset Performance & Reliability: Predict impending

- Production Optimization: Balance rate/pressure,

maximize production, manage bottlenecks and energy use across upstream,

midstream, and downstream assets.

- Production Optimization: Balance rate/pressure,

- Power Generation & Utilities: Improve heat rate and

start/stop strategies; coordinate demand response while honoring safety

and emissions limits.

- Power Generation & Utilities: Improve heat rate and

- Emissions Monitoring & Reporting: Consolidate

measurements and calculations, detect anomalies, and automate mitigation

workflows with full traceability.

- Emissions Monitoring & Reporting: Consolidate

- Customer outcomes: lower unplanned downtime, improved

recovery and throughput, reduced energy intensity and emissions,

consistent operations across shifts and sites.

- Customer outcomes: lower unplanned downtime, improved

- Predictive Quality: Detect drift early, recommend

recipe or machine adjustments, and automatically hold/release lots with

auditable rules.

- Predictive Quality: Detect drift early, recommend

- Throughput & Bottleneck Optimization: Coordinate

line speeds, changeovers, and constraints to raise OEE and stabilize

task time.

- Throughput & Bottleneck Optimization: Coordinate

- Energy & Sustainability: Identify peak drivers,

improve production efficincy, shift loads without risking quality.

- Energy & Sustainability: Identify peak drivers,

- Workforce Augmentation: Standardize best‑practice

playbooks with SmartApps that guide technicians and capture tribal

knowledge.

- Workforce Augmentation: Standardize best‑practice

- Customer outcomes: more production, fewer defects and

rework, less waste, higher OEE, lower energy costs, faster onboarding,

and repeatable, governed autonomy.

- Customer outcomes: more production, fewer defects and

F.A.Q.

Questions? Answers.

Quick answers to questions you may have. Can't find what you're looking for? Please contact us.

No. Databricks complements your historian for large‑scale analytics/ML and Kelvin complements your control system for decisioning and safe automation.

Yes. SmartApps support recommendation‑only, approval workflows, and fully automated modes with guardrails.

Cloud, on‑prem, or hybrid. We integrate with your network zones and security policies.

Teams typically pilot in weeks using our accelerators and expand site‑by‑site with repeatable patterns.

Need more information?

Please reach out if you need more details on a custom solution tailored to your specific needs.